|

|

Assoc. Prof. Dr. Cihan Tekoğlu

Department of Mechanical Engineering

TOBB University of Economics and Technology

Söğütözü Cad. No: 43,

Söğütözü, Ankara, 06560 TURKEY

e-mail: cihantekoglu@etu.edu.tr

phone: +90 (312) 292 40 65

fax: +90 (312) 292 40 91

|

|

|

My

research interests span different areas of macro/micro mechanics of

materials, with a particular focus on metamaterials, and understanding

and improving the fracture behaviour of metals and composites. Although

my main work is devoted to theoretical and computational mechanics, I

have recently started conducting experimental studies as well. In the

following, I briefly state my expertise and give an outlook on my

future research plans.

Metamaterials

Evolutionary

optimization has led natural materials to have remarkably efficient

mechanical properties: wood has a specific strength comparable with

that of the strongest steel, the fracture toughness of bone is an order

of magnitude larger than engineering ceramics, etc. Yet, there is

nothing special about the mechanical properties of the individual

blocks, but it is the arrangement of these building blocks, i.e. the

micro-architecture, which optimizes the mechanical performance. The

ever-increasing demand for multi-functional engineering materials

forces scientists and engineers to develop novel strategies to combine

usually contradicting properties, such as high strength and high

ductility, or high stiffness and low actuation energy, in a single

material. Some topics of interest for me are:

|

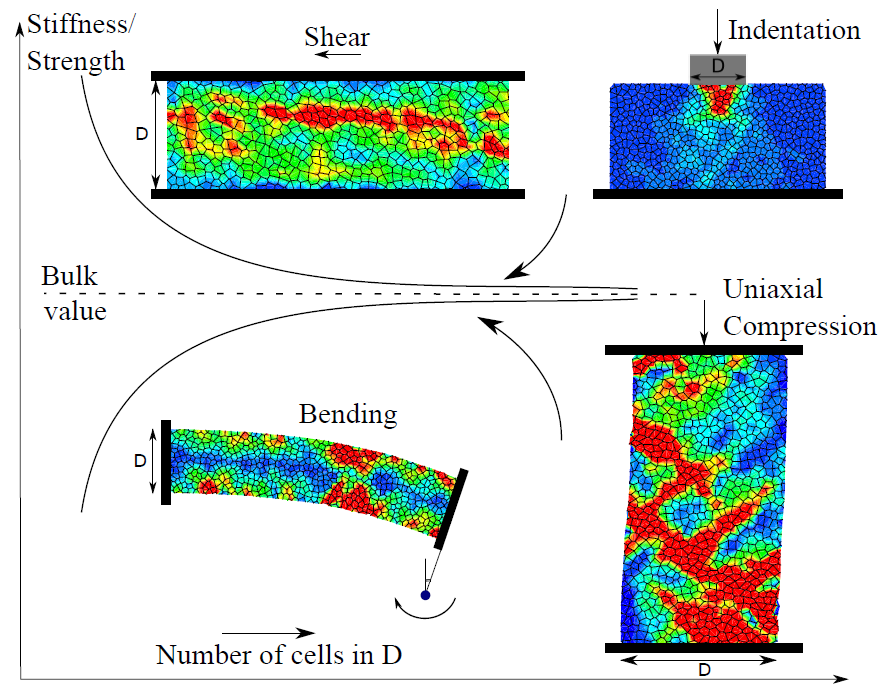

Figure 1: Size-effects

observed for 2D Voronoi microstructures under different loading

conditions. The contour plots show typical strain localization patterns

[4].

|

Cellular solids, which

are a relatively new class of engineering materials with a great

potential to be used in strong, stiff and lightweight structures.

Despite their superior bulk properties, if one of the structural

dimensions of a cellular solid has the same order of magnitude as the

cell size, the effectivemacroscopic response of the solid is dictated

by the individual excitements of the cells, which results in

size-dependent mechanical properties [1]. In order to understand the

effect of the cellular morphology on the mechanical behaviour, we

performed finite element (FE) calculations on model materials [2, 3,

4], see e.g. Fig. 1. By comparing the results with generalized

continuum theories, which incorporate a length scale to capture size

effects, we critically assessed the capabilities of different theories

in the elastic deformation range. The best agreement is obtained for

the strain divergence theory that we proposed, where the divergence of

strain is taken as an additional deformation measure [3].

|

|

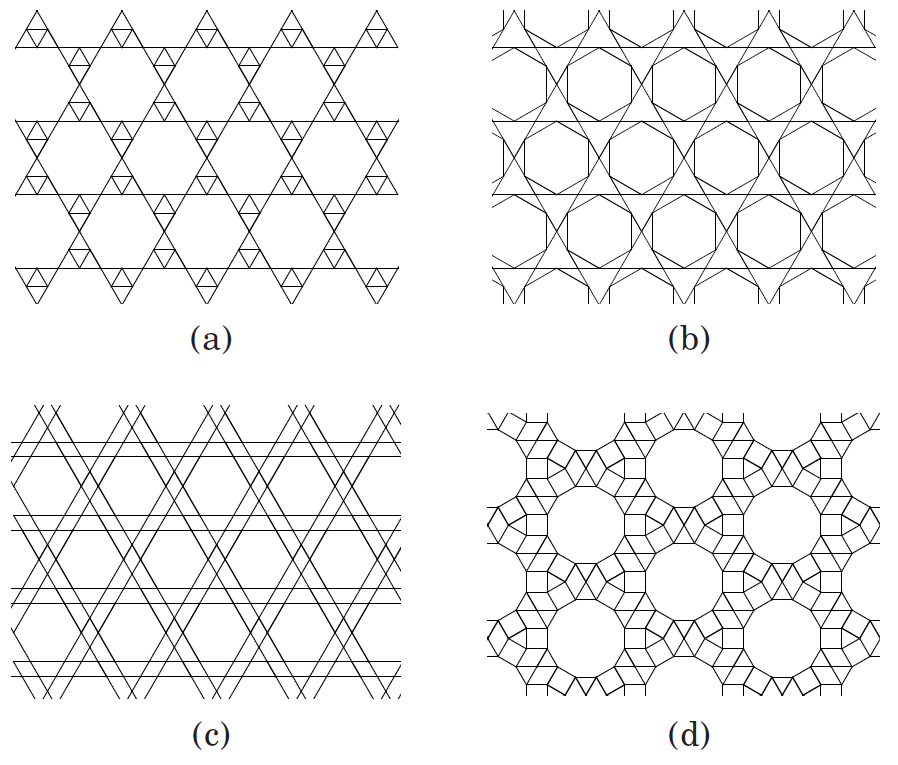

Design of multi-functional materials, which combine mechanical functions (such as stiffness and strength) witho ther

properties (such as thermal or electrical conductivity, shape changing

capability, etc.). Recent studies have shown that some lattice

materials (e.g. two-dimensional (2D) Kagome structure and its 3D

equivalent [5]) have a great potential to be used in multi-functional

applications: if one of the lattice elements (i.e. beams or rods) is

replaced with an actuator, the material can undergo large shape changes

when the actuator is deployed, while it provides stiffness against

external loads when the actuator is not triggered. The Kagome lattice

is a member of the family of semi-regular tessellations of the plane.

Two fundamental questions naturally arise: i-) What makes a lattice

material suitable for actuation? ii-) Are there other tessellations

more effective than the Kagome lattice for actuation? In order to

answer these questions, we first established a set of topological

criteria to identify micro-architectures suitable for actuation [6],

and determined the sufficient symmetry conditions for isotropy of

elastic moduli [7]. We then contrived four novel 2D in-plane isotropic

lattice materials in light of these criteria [8], see Fig. 2. One of

the proposed designs (the Double Kagome lattice, see Fig.

2c) is found to match the optimal elastic properties of the Kagome

structure, while it requires less energy for (single member) actuation.

The only downside of the DK lattice appears to be that the displacement

field induced by actuation attenuates faster than in a Kagome lattice,

meaning that the DK lattice has a lower shape changing capacity.

Figure 2: The

four newly contrived 2D lattice materials: (a) Kagome with concentric

triangles (KT), (b) Kagome with concentric hexagons (KH), (c) Double

Kagome (DK), and (d) the Modified Dodecagonal structure (MD).

|

My quest for stiff/strong shape-morphing lattice materials progresses

with fruitful outcomes. Recently, I designed two different families of

2D in-plane isotropic lattice materials, and some members of both

families turned out to possess a negative Poisson ratio (NPR). Owing

the their underlying architecture, NPR materials offer attractive

mechanical properties. For example, unlike a positive Poisson ratio bar

or plate, which assumes a saddle shape when bent, NPR materials take

convex shapes that are more appropriate for sandwich panels for

aircraft or automobiles, see e.g. [9, 10]. With their high resistance

to shear and indentation, and high energy absorption capacity and

toughness, NPR materials have a large potential to be used in different

applications such as fasteners and rivets, sensors, medical

applications (e.g. artificial blood vessels), bullet-proof helmets and

vests, intelligent textiles, internal structure for adaptive airplane

wing box configurations, etc. My research group currently characterizes

the mechanical properties of the NPR materials that I designed. These

new materials cover a relatively large range of different NPR values,

and some of them

|

have higher stiffness values compared to the existing

2D NPR lattices. In the long term, I am planning to extend (some) of

these 2D lattice designs to 3D, that could for example be used in

crashworthiness applications.Ductile fracture of metals and composites

The

mechanical properties of structural metallic alloys are continually

improved such that cleavage and intergranular fracture mechanisms are

mostly successfully avoided, leaving ductile fracture as the main

failure mechanism upon overloading. Therefore, together with fatigue

and corrosion, ductile fracture is the key ingredient in structural

integrity assessment of metals. Most of the ductile fracture models in

the literature neglect the presence of second-phase particles and make

use of phenomenological stress and/or strain controlled void nucleation

laws, where the nucleation stress/strain values are defined with

respect to the overall values in the material, and not to the local

field quantities in the particles or along the particle-matrix

interfaces. If, however, the particle volume fraction is larger than

5-10 %, neglecting the presence of the particles leads to dramatically

poor estimates for the fracture strain. In order to explicitly account

for the effect of second phase particles on the ductile fracture

process, we integrated a damage model based on the

Gologanu-Leblond-Devaux (GLD) constitutive behavior with a mean-field

homogenization scheme [11]. The integrated model is able to account for

the per-phase and overall stress/strain response of the material, and,

as importantly, for the softening induced by particle fracture or

decohesion, which cannot be captured by regular Gurson type models due

to a lack of coupling between void nucleation and particle response

[12]. The proposed model is shown to successfully predict the fracture

strain of dual-phase (DP) [13]. I have successfully completed a project

funded by The Scientific and Technological Research Council of Turkey

(T¨UB˙I TAK), entitled “Microstructural optimization of dual-phase (DP)

steels”, and I am planning to extend the approach we used to study the

DP steels to a wide class of metallic alloys, such as TRIP steels and

Titanium alloys.

In

order to address the effect of crystal plasticity on growth and

coalescence of voids in single crystals, we performed a large set of FE

calculations on 3D representative unit cells containing a spherical

void. We were able to predict the onset of void coalescence by using

the Thomason criterion—which was initially developed in the framework

of isotropic perfect plasticity—within 20 % relative error for most

cases, and often more accurately [14]. A more challenging task is to

provide a constitutive damage model that can account for plastic

anisotropy. For this purpose, we coupled the Gurson model with an

anisotropic yield criterion, the Facet method, which successfully

represents the yield surfaces of both single and polycrystals, even for

sharp crystallographic textures [15].

I have also contributed

to the extension of the GLD model to account for the rotation of the

voids. We proposed a void rotation law and showed that it gives

excellent agreement with 3D unit cell calculations [16]. We have also

coupled the GLD damage model with a more realistic, Kocks-Mecking type

strain hardening law, which explicitly takes into account the two main

strain hardening stages observed in metals, referred to as stage III

and stage IV in the literature. The predictions of this extended damage

model are in very good agreement with the results of the FE voided unit

cell calculations [17]. A comprehensive summary for a part of my work

on fracture mechanics is explained in a review paper [18].

Although

there exists fairly accurate (theoretical/numerical) models for void

growth, especially for isotropic materials, proper treatments of void

nucleation and localization of plastic deformation leading to final

failure are still open research topics. An important part of my work

concerning fracture mechanics is therefore devoted to the development

ofmicroscopic localization (i.e. void coalescence) criteria

incorporating the effect of shear loads [19, 20], and the effect of the

presence of a secondary family of voids/particles [21]. I have also

worked on macroscopic plastic localization dominated failure, which led

to the important conclusion that: “At sufficiently high stress

triaxiality, a clear separation exists between the macroscopic and

microscopic modes of localization. At lower stress triaxialities,

however, the onset of macroscopic localization and coalescence occurs

simultaneously” [22]. All these studies on localized deformation gave

me the opportunity to build a robust FE framework for performing

representative volume element calculations under constant stress

triaxiality, Lode parameter, and shear ratio [23]. I have ongoing

studies on failure under low stress triaxiality, with a particular

interest on the effect of “shear ratio” on ductile fracture. An

ambitious target for me is to develop a localization model for randomly

distributed and oriented voids/particles under general loading

conditions.

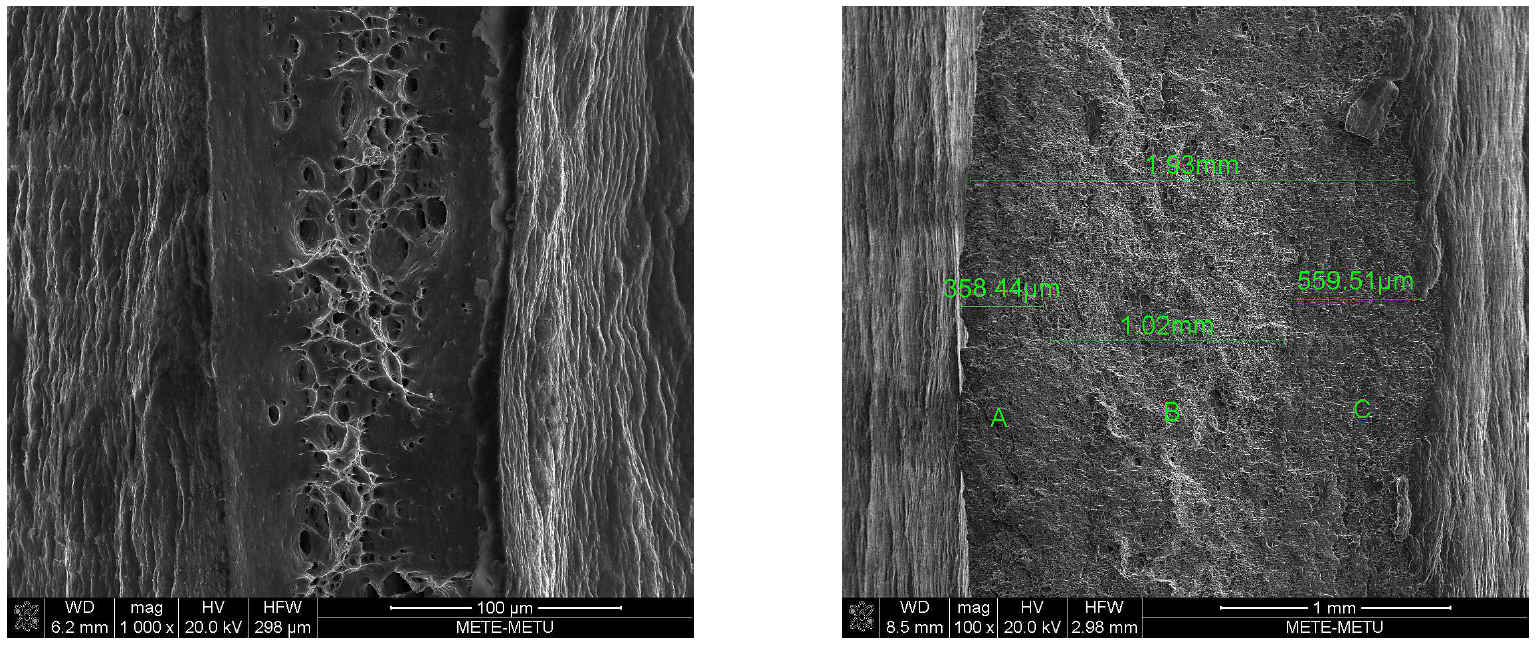

Another

challenging topic in the field of ductile fracture is the effect of

volume fraction, shape, size and spatial distribution of second phase

particles on the crack propagation mechanisms. I have recently

completed a project funded by T¨UB˙ITAK, entitled “A numerical and

experimental investigation of crack propagation mechanisms in ductile

metal plates”. The main conclusion of this study was that “large

particles with a large volume fraction lead to a slanted or a cupcone

crack, while small particles with a small volume fraction lead to a

cup-cup fracture surface morphology for ductile plates teared under

mode I loading (see Fig. 3)”, which we were able

to demonstrate both in an experimental [24] and in a numerical framework [25].

(a)

(b)

|

References[1] C. Tekoğlu, 2007. Size effects in cellular solids. PhD Thesis, University of Groningen, The Netherlands. (url)

[2] C. Tekoğlu, P. R. Onck, 2005. Size effects in the mechanical behavior of cellular materials. J. Mater. Sci. 40, 5911-5917. (url)

[3] C. Tekoğlu,

P. R. Onck, 2008. Size effects in two-dimensional Voronoi foams: A

comparison between generalized continua and discrete models. J. Mech.

Phys. Solids 56, 3541-3564. (url)

[4] C. Tekoğlu, L. G. Gibson, T. Pardoen, P. R. Onck, 2011. Size effects in foams: Experiments and modeling. Prog. Mater. Sci. 56, 109-138 (url)

[5]

N. A. Fleck, V. S. Deshpande and M. F. Ashby, 2010. Micro-architectured

materials: past, present and future. Proc. R. Soc. A. (published

online). (url)

[6] T. N. Pronk, C. Ayas, C. Tekoğlu, 2017. A quest for 2D lattice materials for actuation. J. Mech. Phys. Solids 105, 199-216. (url)

[7] C. Ayas, C. Tekoğlu, 2018. On the sufficient symmetry conditions for isotropy of elastic moduli. J. Appl. Mech. 85, 074502-074502-5. (url)

[8] W. E. D. Nelissen, C. Ayas, C. Tekoğlu, 2019. 2D lattice material architectures for actuation. J. Mech. Phys. Solids 124, 83-101. (url)

[9] S. R. Lakes, 1993. Advances in negative Poisson’s ratio materials Advanced Materials 5, 293-296. (url)

[10] S. R. Lakes, 2017. Negative-Poisson’s-Ratio Materials: Auxetic Solids Annual Review of Materials Research 47, 63-81. (url)

[11] M. Inanc, T. Pardoen, C. Tekoğlu,

2015. An Enhanced Mori-Tanaka Homogenization Scheme for Incremental,

Non-Linear Rate-Independent Plasticity. In: Proceedings of the 5th

ECCOMAS Thematic Conference on the Mechanical Response of Composites,

COMPOSITES 2015, 07-09 September, 2015, University of Bristol, UK

[CD-ROM].

[12] C. Tekoğlu, T. Pardoen, 2010. A micromechanics based damage model for composite materials. Int. J. Plasticity 26, 549-569. (url)

[13] A. P. Pierman, C. Tekoğlu,

T. Pardoen, P. J. Jacques, 2009. Nucleation, growth and coalescence of

voids in dual phase steels: from model microstructures to

microstructure based modeling. In: Proceedings of the 12’th

International Conference on Fracture, Ottawa, Canada [CD-ROM].

[14] S. K. Yerra, C. Tekoğlu,

F. Scheyvaerts, L. Delannay, P. Van Houtte, T. Pardoen, 2010. Void

growth and coalescence in single crystals. Int. J. Solids Structures

47, 1016-1029. (url)

[15] S. K. Yerra, C. Tekoğlu,

A. Van Bael, L. Delannay, P. Van Houtte, T. Pardoen, 2010. The

Facet-Gurson model for ductile damage process. In: 18’th European

Conference on Fracture, August 30 - September 03, 2010, Dresden,

Germany, [CD-ROM].

[16] F. Scheyvaerts, P. R. Onck, C. Tekoğlu,

T. Pardoen, 2011. The growth and coalescence of ellipsoidal voids in

plane strain under combined shear and tension. J. Mech. Phys. Solids

59, 373-397 (url)

[17] L. Lecarme, C. Tekoğlu,

T. Pardoen, 2011. Void growth and coalescence in ductile solids with

stage III and stage IV strain hardening. Int. J. Plasticity 27,

1203-1223. (url)

[18] T. Pardoen, F. Scheyvaerts, A.Simlar, C. Tekoğlu, P. R. Onck, 2010. Multiscale modeling of ductile failure in metallic alloys. C. R. Physique 11, 326-345. (url)

[19] C. Tekoğlu,

J.-B. Leblond, T. Pardoen, 2012. A criterion for the onset of void

coalescence under combined shear and tension. J. Mech. Phys. Solids 60,

1363-1381. (url)

[20] M.E. Torki, C. Tekoğlu,

J.-B. Leblond, A.A. Benzerga, 2017. Theoretical and numerical analysis

of void coalescence in porous ductile solids under arbitrary loadings.

Int. J. Plasticity 91, 160-181. (url)

[21] C. Tekoğlu, 2015. Void coalescence in ductile solids containing two populations of voids. Eng. Fract. Mech. 147, 418-430. (url)

[22] C. Tekoğlu,

J.W. Hutchinson, T. Pardoen, 2015. On localization and void coalescence

as a precursor to ductile fracture. Philos. T. R. Soc. A. 373, 1-9. (url)

[23] C. Tekoğlu,

2014. Representative volume element calculations under constant stress

triaxiality, Lode parameter, and shear ratio. Int. J. Solids Struct.

51, 4544–4553. (url)

[24] C. Tekoğlu,

S¸ . C¸ elik, H. Duran,M. Efe, K. L. Neilsen, submitted. Experimental

Investigation of Crack Propagation Mechanisms in Commercially Pure

Aluminium Plates. To: Proceedings of 1st International Workshop on

Plasticity, Damage and Fracture of Engineering Materials (IWPDF2019),

August 22-23, 2019, Ankara, Turkey.

[25] C. Tekoğlu,

K. L. Nielsen, 2019. Effect of damage-related microstructural

parameters on plate tearing at steady state. Eur. J. Mech. A-Solid.

Advance online publication. (url)

|

|